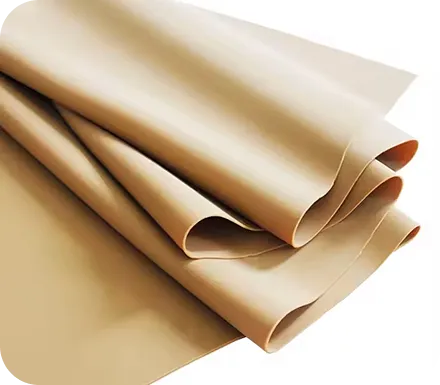

DuraBlast65 Max: Natural rubber sheet

What is DuraBlast65 Max?

The DuraBlast65 Max, with its hardness of 65 ± 5° Shore A is a premium-grade natural rubber sheet developed to offer exceptional strength, resilience, and versatility for demanding industrial applications. It is ideal for heavy-duty applications. The physical properties of DuraBlast65 Max, including its high elongation at break of 350% and tensile strength of 10 MPa offer superior performance in demanding environments.

Whether the requirement is of 2.5 mm rubber sheet, a 12 mm thick rubber sheet, or any other thicknesses or dimensions, customization is available. This rubberized sheeting has extensive applications in the industries such as automotive, manufacturing, oil & gas, logistics, and more.

DuraBlast65 Max is available in both industrial-grade black and aesthetically refined color variants (Tan, Off White, and Red) to meet specific workplace or visual management needs.

Check out below for their technical specifications:

Technical Specifications of DuraBlast65 Max Rubber Sheet

| MEASURED PROPERTIES | TESTING STANDARD | SPECIFIED VALUES | OBSERVED VALUES |

|---|---|---|---|

| Tensile Strength | ASTM D412 | 10.0 MPa (min) | 10.5 MPa |

| Elongation at Break | ASTM D412 | 350% (min) | 381% |

| Hardness | ASTM D2240 | 65° ± 5° Shore A | 66° Shore A |

| Specific Gravity | ASTM D297 | 1.25 ± 0.05 | 1.26 |

| Working Temperature | – | -20°C to +70°C | Conforms |

| STANDARD DIMENSIONS & POLYMER COMPOSITION | |||

| Size | 2~12mm Thk. x 1.2m Wide x 10m Long | Finish Type | Top & Bottom Plain |

| Color | Black, Tan, Off-White, Red | Polymer | NR/SBR |

Key Features and Properties of DuraBlast65 Max

Stress Endurance

Withstands high stress in demanding applications without failure.

Balanced Hardness

Hardness that ensures a perfect mix of flexibility and strength.

Mechanical Durability

With tensile strength of 10 MPa and 350% elongation at break, it is highly durable.

Color Options

Available in color variants- tan, red, off-white, and black.

Smooth surface

Smooth surface finish that is easy to clean and maintain.

Wear Resistance

Does not wear out even in abrasive industrial environments.

Common Uses of DuraBlast65 Max rubber sheet

- Heavy-duty gaskets and mechanical seals in non-oil setups

- Vibration-isolation pads for light to medium equipment

- Wear pads and floor liners in assembly and packaging areas

- Protective padding for engineering workbenches and storage units

- Shock absorbing mats in loading docks or conveyor systems

- Visual safety zoning in manufacturing with colored variants

- General-purpose padding in high-footfall industrial areas

Industry Certifications And Memberships

Why Duratuf for DuraBlast65 Max rubber sheet?

Quality Consistency

Tested products that guarantee the specifications meet the quality standards.

Global Supply

We regularly export our rubber sheets to more than 61+ countries worldwide.

Best Bulk Rates

Competitive pricing offered for large-volume orders with tiered discounts.

Sales Support

High-end pre-sales and after-sales support enhances customer experience.

Our Client Testimonial / Success Stories

Omar Hassan

I must say that Duratuf Products provided me EPDM rubber sheets of top quality. The sheets delivered by you guys are perfect for applying in my workplace’s industrial tanks! The order was delivered to us on time so a big thanks to you people.

Chris Taylor

On-time delivery: Thank you Duratuf for the EPDM rubber sheets of top quality. The sheets delivered by you guys are best for applying in my workplace’s industrial tanks! The order was delivered to us on time so a big thanks to the sales and support team.

Sakshi B

I’ve long sought a dependable solution for our sealing applications. Thanks to your Viton Rubber Sheets, our search is finally over. These sheets have revolutionized our sealing processes, offering unparalleled resistance to extreme temperatures, chemicals, and pressure.

Rajiv Barua

The Nitrile Rubber Sheets exhibit exceptional resistance to oils, fuels, and abrasion, making them ideal for our demanding applications in the automotive sector. Very happy with customer services.

Anil Patel

Thanks to Duratuf’s reliable products, we’ve achieved higher operational efficiency and productivity levels. I wholeheartedly endorse their Skirt Board Rubber Sheets to fellow industry professionals seeking dependable performance.

Anita Singh

As the proprietor of a manufacturing unit in Kolkata, India, I’ve relied on Neoprene Rubber Sheets from Duratuf to meet our demanding industrial requirements. The Neoprene material’s resilience against abrasion, weathering, and oil has significantly enhanced the durability of our products.

Vikram Singh

As a steel fabrication company based in Mumbai, India, maintaining the integrity of our equipment is essential. These rubber sheets have significantly enhanced the efficiency and safety of our blasting processes.

Suresh Menon

The quality and reliability of your pulley lagging sheets are very good. They provide exceptional traction and wear resistance, even under the most demanding conditions. Our machinery’s performance has improved significantly since we started using these sheets, reducing downtime and maintenance costs.

Rajesh Kumar

Living in Chennai, India, I’ve struggled to find a reliable solution for my industrial needs until I discovered Silicone Rubber Sheets from Duratuf. The quality of the silicone is impeccable, offering unmatched resistance to extreme temperatures and chemicals, crucial for our diverse applications.

Steven Miller

After placing my first order, I was thoroughly impressed with Duratuf’s easy ordering process and attention to the customer’s needs. The insertion rubber sheet provided to us has surpassed my expectations, proving to be an essential component in our production line.

Sarah Johnson

I run a small manufacturing unit specializing in inflatable products. We recently switched to Hypalon rubber sheets supplied by Duratuf for our production line, and the difference has been remarkable.

R. Patel

As a customer based in London, I’ve been thoroughly impressed by the Natural Rubber Sheet offered by Duratuf. Its eco-friendly composition aligns perfectly with my values.

Anastasia Ivanova

Being in the heart of monsoon-prone Mumbai, finding a reliable waterproofing solution was paramount for our construction project. We chose the EPDM Rubber sheets, and it has exceeded our expectations. Thanks to this innovative product, our investment is protected for years to come. Highly recommend it to fellow developers!

Omar Hassan

I must say that Duratuf Products provided me EPDM rubber sheets of top quality. The sheets delivered by you guys are perfect for applying in my workplace’s industrial tanks! The order was delivered to us on time so a big thanks to you people.

João Pereira

I recently purchased Butyl Rubber Sheets for a project, and I must say, I am thoroughly impressed with their quality and performance.

Diego Martinez

The Abrasion Resistant Rubber Sheet exceeded our expectations, providing exceptional protection against wear and tear.

Oliver Smith

The General Purpose Rubber Sheet is a game-changer for us. It seals effectively, withstands extreme conditions, and saves time and resources. Highly recommended for reliable sealing and insulation

Bruce Budden

Insulated mat from Duratuf Products are not like other common commercial rubber mats. Easy to use, flexible, durable and the best quality at affordable price. I strongly recommended these to ensure the safety of workplace.

Ajinkya Vartak

We have purchased insulating mats from Duratuf because of their high quality. I appreciate Mr. Samsul Haque sir as he handled dispatch and product quality. Mr. Debapriyo Nandi, logistic Coordinator assists for transportation & excellent packing quality.

Suresh Babu Dasari

Quality of the products are reallly good and trustworthy. People of this organization are very professional and proactive.

Frequently Asked Questions

What is DuraBlast65 Max rubber sheet used for?

DuraBlast65 Max is used for impact-absorbing pads, anti-vibration liners, protective surface covers, sealing applications, conveyor support liners, and cushioning for industrial equipment. It is ideal for clean, non-oily industrial zones.

What is the hardness of DuraBlast65 Max?

The sheet has a nominal hardness of 65 ± 5 Shore A (ASTM D2240), providing enhanced firmness compared to softer grades while maintaining shock absorption.

What are the tensile strength and elongation values?

As per ASTM D412, Tensile Strength: Minimum 10.0 MPa (Observed 10.4 MPa) and Elongation at Break: Minimum 350% (Observed 377%). These values ensure excellent durability, stretchability, and long service life under load.

What is the specific gravity of DuraBlast65 Max?

The specific gravity is 1.25 ± 0.05 (Observed 1.26) as per ASTM D297, providing a balanced density for cushioning and structural support.

What is the working temperature range?

DuraBlast65 Max operates effectively within –20°C to +70°C, making it suitable for various indoor industrial applications.

Is DuraBlast65 Max resistant to oils and chemicals?

DuraBlast65 Max offers fair ozone resistance, but it is not recommended for exposure to oils, solvents, or concentrated/dilute acids and bases. It performs best in dry, non-oily environments.

Does DuraBlast65 Max have a plain finish?

Yes. The sheet features a plain finish on both top and bottom surfaces, enabling accurate die-cutting, punching, bonding, and easy installation.