Pulley Lagging Sheets

Duratuf pulley lagging rubber sheets have three products in their category starting from the general grade, moderate-duty, and premium one. They are made from flexible, natural rubber polymer with tested resilience against wear, tear, abrasion, and material damage.

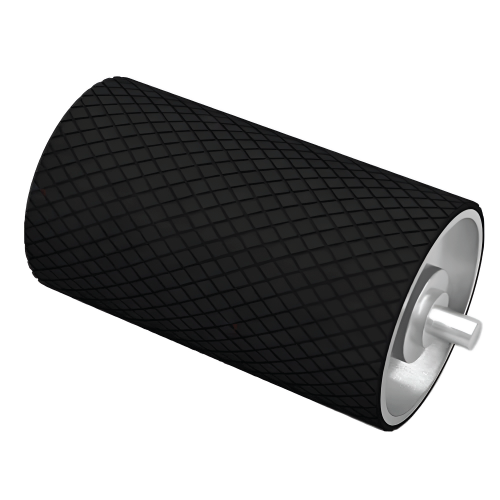

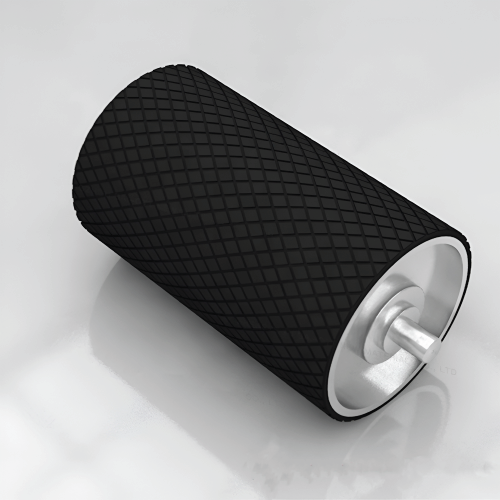

Our pulley lagging rubber sheets are engineered in a way that effectively decreases friction with the conveyor belt and protects the shell from damage. We offer both plain pulley lagging rubber sheets and diamond-grooved rubber lagging.

The plain rubber lagging sheets are designed for non-drive pulleys while the diamond rubber lagging sheets are for pulleys that require more friction on the conveyor belt.

Discover the product details here:

Pulley Lagging Sheets : Product Variants

DuraPulley65 Pro

High-performance product for medium to heavy-duty material handling systems …

DuraPulley60 Max

Premium-grade product of 100% natural rubber developed for high-stress, conveyor systems …

DuraPulley60 X

Economical, general-purpose product that provides basic anti-slip performance and abrasion resistance

Pulley Lagging Rubber Sheet: Comparison Between the Variants

| Item Name | Grade | Polymer | Color | Tensile Strength | Elongation at Break | Specific Gravity | Hardness | Abrasion | Surface Finish | Thickness | Max. Width | Max. Length | Recommended Use Temp. Range (°C) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DuraPulley60 X – Black | X | NR/SBR | Black | 5 MPa (min) | 250% | 1.40 ± 0.05 | 60 ± 5° Shore A | 300 mm³ (max) | Top – Diamond & Bottom – Textured | 8/10/12/15 mm | <=2400 mm | <=20 m | -10° to + 70° C |

| Top – Plain & Bottom – Textured | |||||||||||||

| DuraPulley65 Pro – Black | PRO | NR/SBR | Black | 10 MPa (min) | 350% | 1.25 ± 0.05 | 65 ± 5° Shore A | 200 mm³ (max) | Top – Diamond & Bottom – Textured | 8/10/12/15 mm | <=2400 mm | <=20 m | -20° to + 70° C |

| Top – Plain & Bottom – Textured | |||||||||||||

| DuraPulley60 Max – Black | MAX | NR/SBR | Black | 15 MPa (min) | 450% | 1.15 ± 0.05 | 60 ± 5° Shore A | 150 mm³ (max) | Top – Diamond & Bottom – Textured | 8/10/12/15 mm | <=2400 mm | <=20 m | -30° to + 70° C |

| Top – Plain & Bottom – Textured |

Major Application Areas of our Pulley Lagging Rubber Sheets

- Light-Duty Conveying Applications: Used in warehouses, logistics, food distribution, packaging, and small-scale manufacturing for smooth handling of lightweight materials.

- Medium-Duty Processing Lines: Ideal for batching plants, dry goods, agricultural produce, and local cement or chemical processing with moderate capacity needs.

- High-Volume Industrial Conveying: Supports mining, quarrying, cement, bulk storage, and high-speed packaging where consistent high-throughput is critical.

- Heavy-Duty Material Handling: Designed for steel plants, foundries, power stations, and large-scale industrial sites managing continuous heavy-load operations.

- Extreme-Duty Belt Systems: Built for ports, power plants, and mineral processing units requiring premium-grade durability under intense operational stress.

FAQ

We deliver all across India and every part of the world from our warehouses and through our dedicated channel partners.

The price of our pulley lagging rubber sheet depends on the variants you are choosing, quantity, and sizes. Therefore, we suggest you talk to us directly for our silicone sheet price.

Standard pulley lagging sheet sizes are usually shipped within 2–4 business days, while custom orders may take more, depending on complexity and quantity.

As one of the leading pulley lagging rubber sheet suppliers, we plan and maintain our product inventory using high-end technology. Therefore, stay assured about getting on-time delivery*.

Talk to us to get a better idea of the timeline.

*under normal circumstances

Yes, our team provides application guidance and free product selection consultation sessions to help you.

We also provide product samples on request to help with material evaluation. Call, WhatsApp, or Mail to us if you need any such assistance.

We test every batch of pulley lagging rubber sheets to make sure they adhere to all the compliance and quality parameters. Still, if you have any complaints regarding our product, connect with us. We take customer feedback seriously and will try to resolve your issue as fast as we can.

Yes, we provide pulley lagging rubber sheet customizations. Apart from the length, thickness, and width, you can talk to us about custom hardness, tensile strength, insertions, and more. Connect with us to discuss.