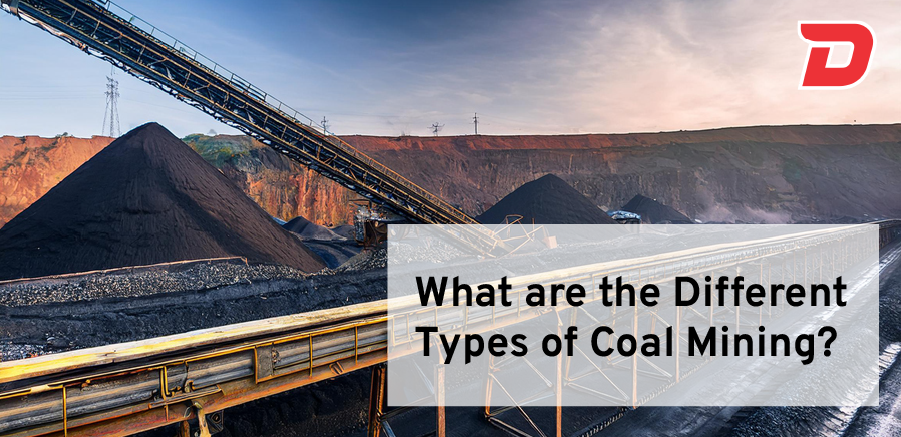

Coal, an important fossil fuel, is a vital source of energy. To make it simple- coal runs the world of power generation. But, are they easy to extract? News channels often cover news about accidents in coal mines. What if we say, a rubber mining belt can be a lifesaver?

Coal is difficult to extract. With excessive mining and depletion of natural resources, underground mines often get flooded, causing the workers to get trapped inside. Accidents are not only unfortunate, but they cause business loss too.

A mining belt conveyor plays a versatile role in different types of coal mines. The mining conveyor adds to effectiveness in specific ways. But, what are the types of coal mines?

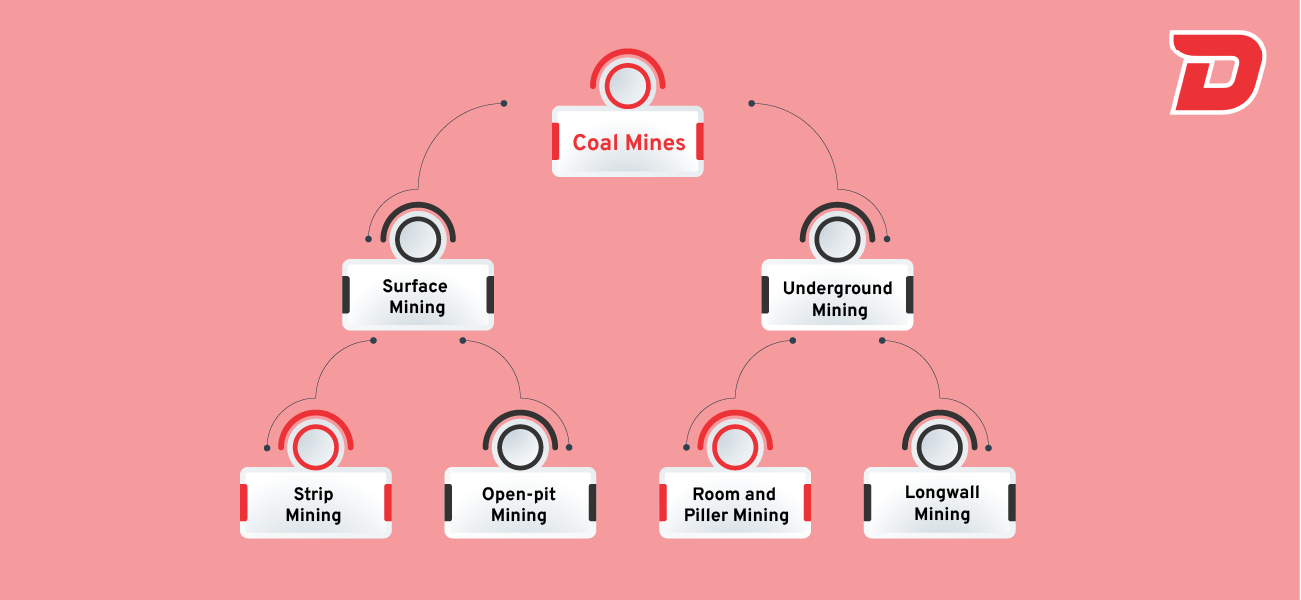

From the names, you get an idea about the nature of the coal mines. For example, in surface mines, layers of coal near the surface are exposed by removing the soil, and in underground mining, coal layers are found deep under the ground.

Are you thinking about how a mining conveyor belt equally contributes to the efficiency of an open as well as an underground mine?

7 Ways in Which a Rubber Mining Belt Makes Your Operations Smarter

Yes, you have read it right. Types of conveyor belt used in mining make you 10x smarter!

How do we know that? Well, our 1000+ mining belt conveyor users vouch for the simplicity and cost savings of a rubber mining belt. Come on, let’s DIG deeper-

Below are seven ways in which a conveyor belt in mining industry is revolutionizing the sector and how it can save users time and money.

Mining Conveyor Making Bulk Material Handling Easy

Tonnes of coal are extracted every day in the mines. A mining conveyor belt streamlines the entire process. The functioning of various parts of a belt mining system in sync ensures continuous and automated coal transport.

Furthermore, the mining belt conveyor connects various points in the mining operation, from extraction sites to processing plants and storage facilities. Thus, it eliminates the need for manual transportation or excessive machinery.

Rubber Mining Belt Durability Endures Extremes

Coal mines are found in areas with harsh weather- geographical places with scorching sunlight, high humidity, and long spells of rainfall. Additionally, the heavy load and sharp edges of coal make it more challenging to transport coal in the mines.

Specialists suggest using a general purpose or M24 heavy-duty rubber mining belt with nylon insertion here. The durable but flexible rubber cover has a long life, even against sharp coal lumps.

Mining Belt Conveyor Adds Safety to the Coal Mines

Every day, more than 10 workers get injured or killed in mining accidents. Hence, safety should be a top priority in mining operations, where even minor accidents can lead to severe consequences. A conveyor belt in underground mining incorporates safety features to mitigate risks:

- Fire Resistance: An FR-grade mining conveyor belt is treated with fire-retardant materials, which is critical for underground mines prone to flammable gases.

- Heat Resistance: In some mining operations, high heat is involved. In such places, using a mining conveyor belt will enhance efficiency while keeping the accidents in check.

- Slip-Resistant Surfaces: Special textures and coatings on belt mining systems prevent materials from sliding back on steep inclines, reducing hazards.

Mining Conveyor Belt is a Sustainable Alternative

Do you know how much pollution does a mine truck cause? According to a research paper by the Rocky Mountain Institute, mining trucks contribute to 30-40% of the mine’s total emissions. Indeed, mining is energy-intensive, and modern mining conveyor belt manufacturers design rubber belts with this in mind.

Belt Mining Cuts Costs Without Compromising the Efficiency

Are you worried about the increasing business costs? Searching ways to master disaster management? Accident compensation is becoming heavy on your pocket?

Install a rubber mining belt now. Conveyor systems will cut down your costs without affecting your efficiency even by a bit.

They save costs across multiple areas:

- Labor Charges: Automated conveyor systems reduce the need for a large skilled workforce to handle coal transportation.

- Fuel and Equipment Costs: Replacing mining trucks with conveyor belts eliminates fuel expenses and the maintenance of vehicles.

- Long-lasting solution: Durable, quality certified mining conveyor belts require fewer replacements and are a long-lasting solution.

Customized Rubber Mining Belt For Unique Mining Needs

The nature of every coal mine is different, and unique challenges like extreme weather, steep slopes, and corrosive environments remain. The good part is, that you can customize a mining conveyor belt as your mining needs demand.

- You can get a fire-resistant or FR-grade rubber mining belt with self-extinguishable properties.

- HR-grade conveyor belts in the mining industry are for tackling the heat that man cannot.

- An M-24 mining belt conveyor is fit for transporting coal lumps with sharp edges.

Mining Belt Conveyor System Drives Productivity with Advanced Technology

You can integrate rubber mining belts with advanced technologies like automated controls, sensors, and real-time monitoring systems. These innovations further enhance productivity and minimize operational disruptions.

- IoT Integration: Sensors installed on mining belts provide data on wear, tension, and load, enabling predictive maintenance and avoiding unexpected failures.

- Smart Controls: Automated systems regulate the mining belt’s speed and load distribution for optimal performance.

Duratuf Rubber Mining Belt For Managing Your Mine Like a Pro!

The Duratuf conveyor belts are crafted with the latest engineering techniques. Having a tough cover and strong reinforcements, our conveyor belts support the operations of industries including mining, construction, agriculture, manufacturing, etc.

You get Duratuf mining conveyor belts in abrasion, fire, heat, or oil-resistant variants.

If you’re a mining operator looking to boost productivity, reduce costs, and improve safety, investing in a high-quality conveyor belt in mining industry is a smart move.

What are you going to do next? Connect with us, of course! Call, mail, or WhatsApp us- you will get an exclusive mining belt conveyor quote within the next hour!