Neoprene sheeting is one of the most popular synthetic rubber sheets. While Neoprene rubber sheeting in its original form is used as floor covers, vibration dampeners, and tank linings, a Neoprene rubber sheet is cut into strips as well.

Neoprene rubber strips are equally versatile and have some unique benefits. However, they too have some limitations. Are you curious to know them? Well, we can promise that this blog is going to convert you from a practical buyer to a smart buyer.

Come, let’s explore why Neoprene rubber sheet manufacturers even cut the sheets into strips:

Why is Neoprene Sheeting Cut Into Smaller Strips?

A Neoprene sheet is cut into smaller strips to improve its functionality, mainly. Neoprene sheeting converted into thinner sizes makes it more valuable in specific applications. Cutting the Neoprene rubber rolls allows them for:

- Custom Sizing: Strips can fit dimensions more precisely, making them suitable for seals, gaskets, or padding in confined spaces.

- Flexible to install: Narrow Neoprene rubber sheet strips are easier to handle, position, and secure during installation, particularly in complex or tight areas.

- Cost Efficiency: Using strips instead of an entire Neoprene sheet minimizes material wastage and reduces overall project costs.

- Improved Performance: The Neoprene rubber sheeting strips allow for better distribution of pressure or load when used as seals or insulation.

Where Can You Use Neoprene Rubber Sheet Strips?

Neoprene sheeting strips are used in:

Neoprene Sheeting Strips in Industrial Applications

Neoprene rubber sheeting strips are a must in industrial applications that have tight sealing requirements. Their resistance to oils, greases, and various chemicals makes them ideal for:

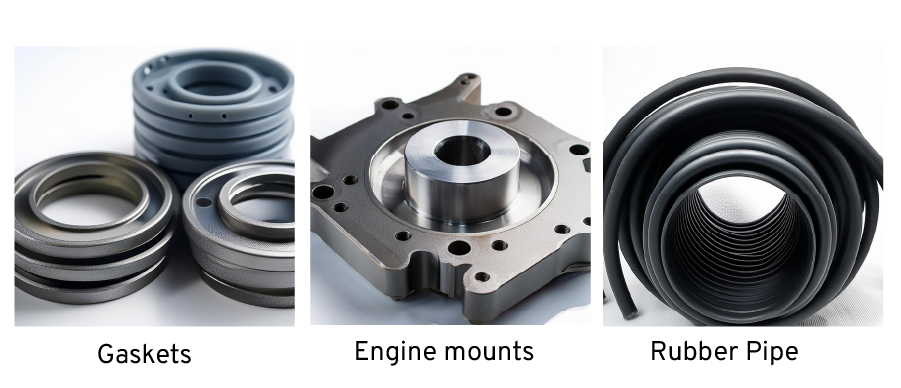

Gaskets and Seals: Gaskets or seals are the smallest yet one of the most critical components in a machine. They prevent the leakage of liquids and gases.

Vibration Dampening: Vibration or high impact may damage valuable machines. Neoprene sheets as machinery mounts save them from the aftereffects.

Pipe Insulation: A Neoprene sheet as a strip reduces heat loss and prevents condensation in industrial piping.

Neoprene Rubber Sheet Strips in Marine Environments

There is constant exposure to salty sea water in marine environments. Nevertheless, compared to other rubber sheeting types, Neoprene rubber remains unaffected. Moreover, a Neoprene sheet strip can also withstand high UV and heat of the open atmosphere:

- Boat Decking: Offering non-slip surfaces and durability against saltwater exposure.

- Dock Fenders: Protecting docks and vessels from impact damage.

- Marine Gaskets: Ensuring watertight seals for underwater equipment.

Neoprene Sheet Strips in Heavy-duty Construction

Do you know what the main problem in heavy-duty construction is? Vibration and impact of heavy machines. Think about what happens during the drilling works. Narrow strips made of Neoprene rubber may look weak, but they are durable and flexible.

- Expansion Joints: Neoprene sheeting as strips absorb structural movement in bridges and buildings.

- Weatherstripping: Door and window seals to prevent air and water leakage. EPDM rubber sheet makes a great option for weatherstripping too.

- Protective Padding: Neoprene sheet strips act as a buffer between materials during construction.

Neoprene Rubber Sheeting in the Automotive Industry

Contact with chemicals, oil, and grease is common in automotive industrial applications. Additionally, the automotive sector frequently uses Neoprene strips for their resilience and resistance to environmental factors:

- Hoses and Belts: Neoprene sheet strips in hoses and belts can sustain high-temperature environments.

- Window Seals: The strips are fitted in the windows of the vehicles for maximum insulation.

- Sound Dampening: Car windows fitted with Neoprene rubber sheeting strips reduce road noise and vibrations.

Neoprene Rubber Strips in Sports and Consumer Goods

Neoprene rubber is synonymous with sportswear and safety equipment due to its flexibility and comfort:

- Wetsuits and Gloves: Offers thermal insulation and resistance to water.

- Fitness Equipment Padding: Enhances comfort and durability in gym equipment.

- Protective Gear: Provides shock absorption in helmets and knee pads.

Neoprene sheeting is versatile, but it has limitations too.

Where You Mustn’t Use Neoprene Sheeting Strips

According to Neoprene rubber sheet manufacturers, you cannot use Neoprene sheet strips in:

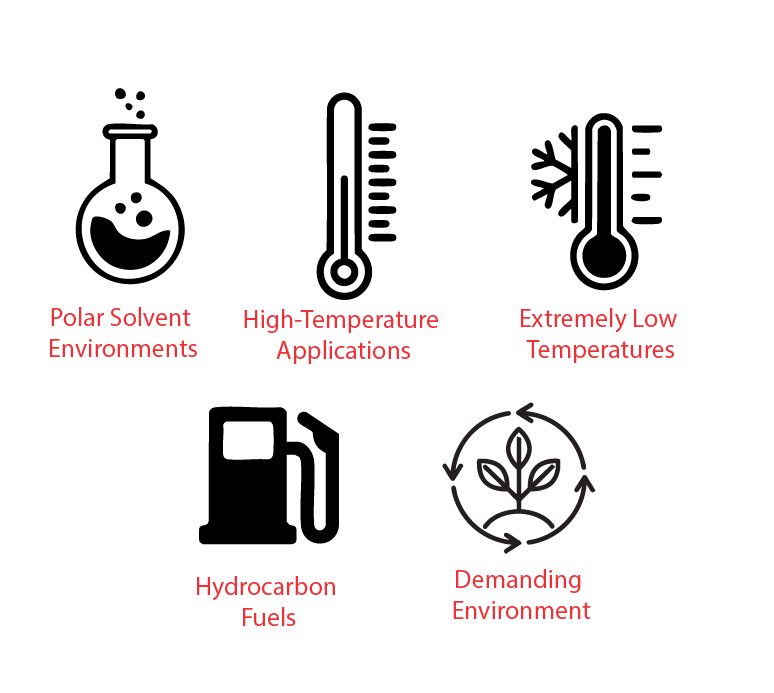

1. Polar Solvent Environments

Neoprene sheeting strips may degrade near highly polar solvents like acetone, ketones, or strong acids and alkalis. Degraded Neoprene rubber won’t work as you have planned.

2. High-Temperature Applications

Neoprene sheets can tolerate moderate heat, but prolonged exposure to temperatures above 120°C (248°F) can cause them to lose elasticity, harden, or crack. Therefore, you should not use them in applications requiring high thermal resistance, such as in furnaces or engines.

Instead, you can use Nitrile rubber sheet strips for the purpose.

3. Extremely Low Temperatures

Neoprene sheeting is not suitable in temperatures below -40°C (-40°F). In such cases, Neoprene becomes brittle and may crack. Thus, it is not ideal for cryogenic applications-that is, in extremely cold environments.

4. Demanding Environment

Neoprene sheeting strips are durable but not designed for environments with heavy abrasion. In highly demanding environments, like mining or quarrying, you may require specialized materials like Nitrile or polyurethane.

5. Hydrocarbon Fuels

Neoprene is resistant to many oils but is not compatible with hydrocarbon fuels like gasoline or diesel. Prolonged exposure can cause swelling, weakening, and failure.

Choosing the Right Neoprene Rubber Strips Starts With a High-Quality Sheet

Yes, if you want unparalleled performance with minimum downtime, you have to start with a quality-attested Neoprene rubber sheet. Furthermore, how do you know you are paying the Neoprene rubber sheet price?

Easy.

First of all, check the reputation of your Neoprene rubber sheet suppliers in the market.

Second, ask about the authenticity of the Neoprene rubber products. A genuine Neoprene rubber sheet should have quality certificates.

Finally, see how the Neoprene rubber sheet supplier is rated on social media and Google. Approximately 56.32% of buyers say that word of mouth has helped them buy Neoprene rubber sheets for their business needs.

Neoprene sheeting strips are a reliable, adaptable solution for a range of industries, from automotive to construction. Do you need help choosing the right Neoprene sheeting strip for your specific application? We are just a call away!